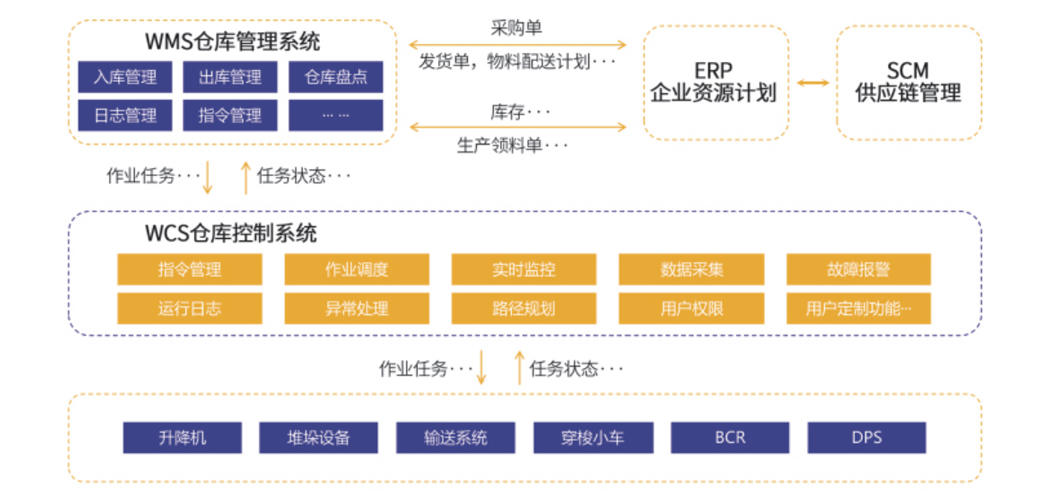

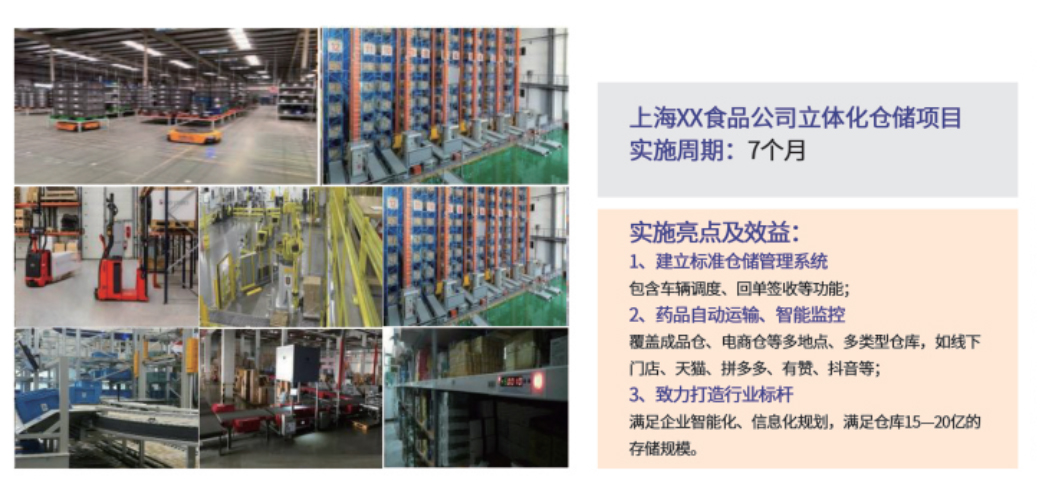

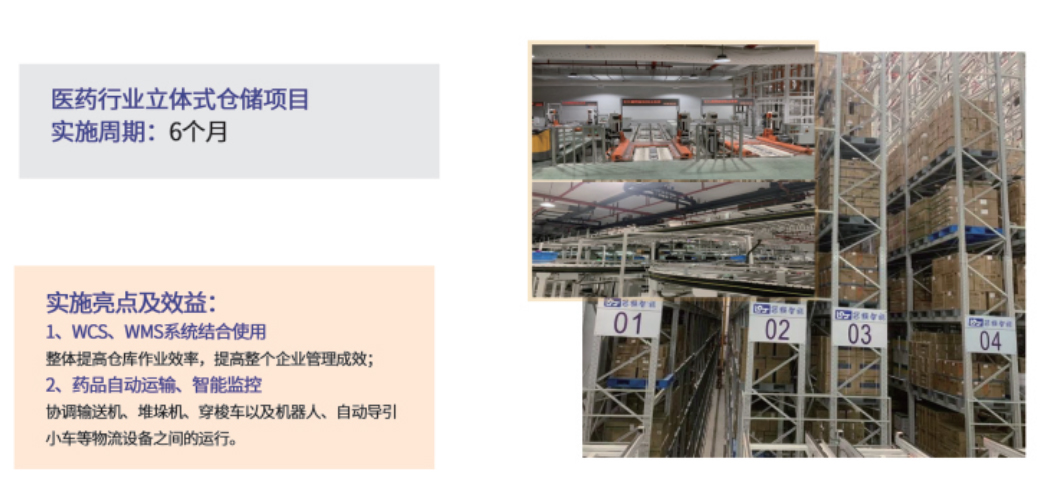

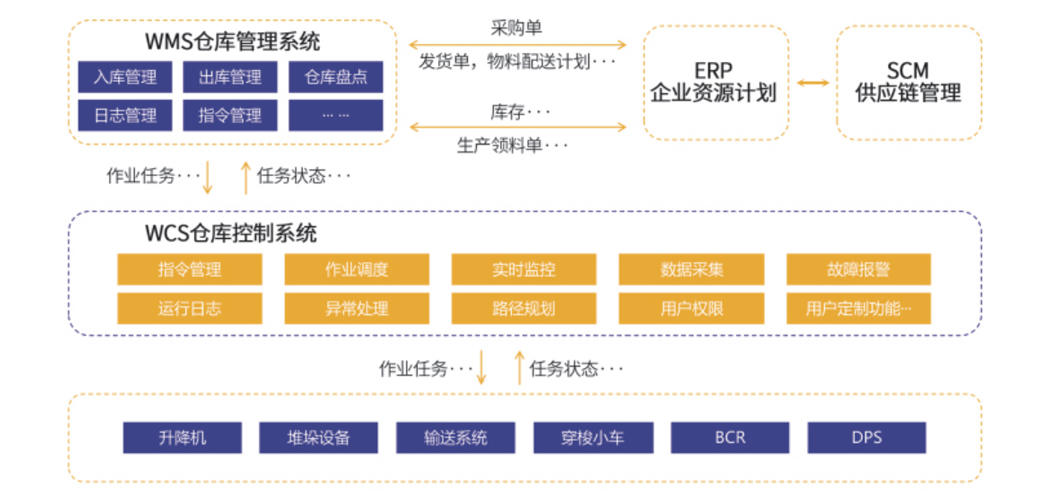

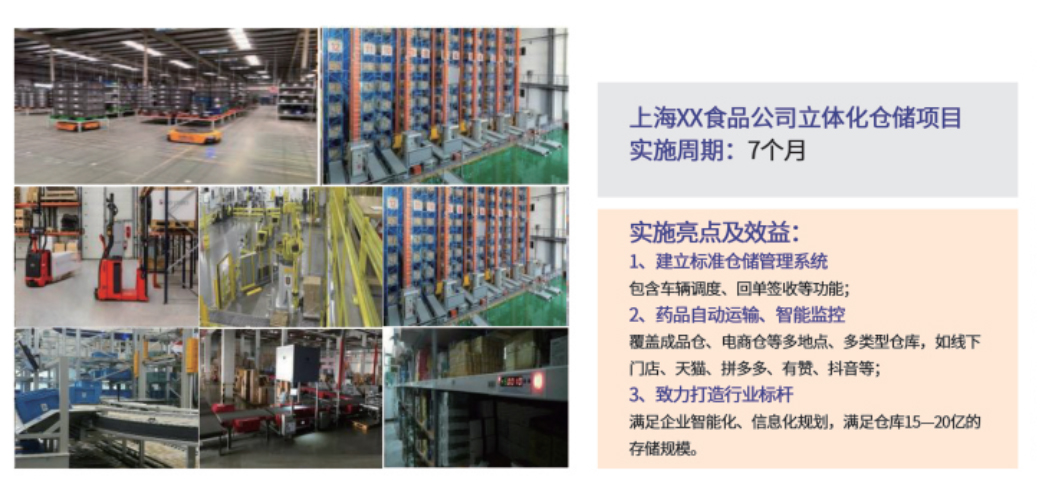

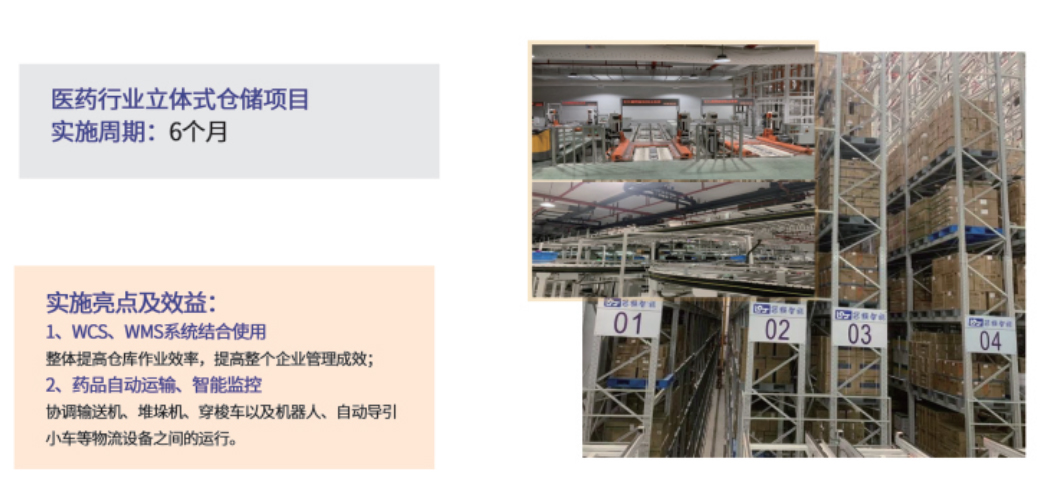

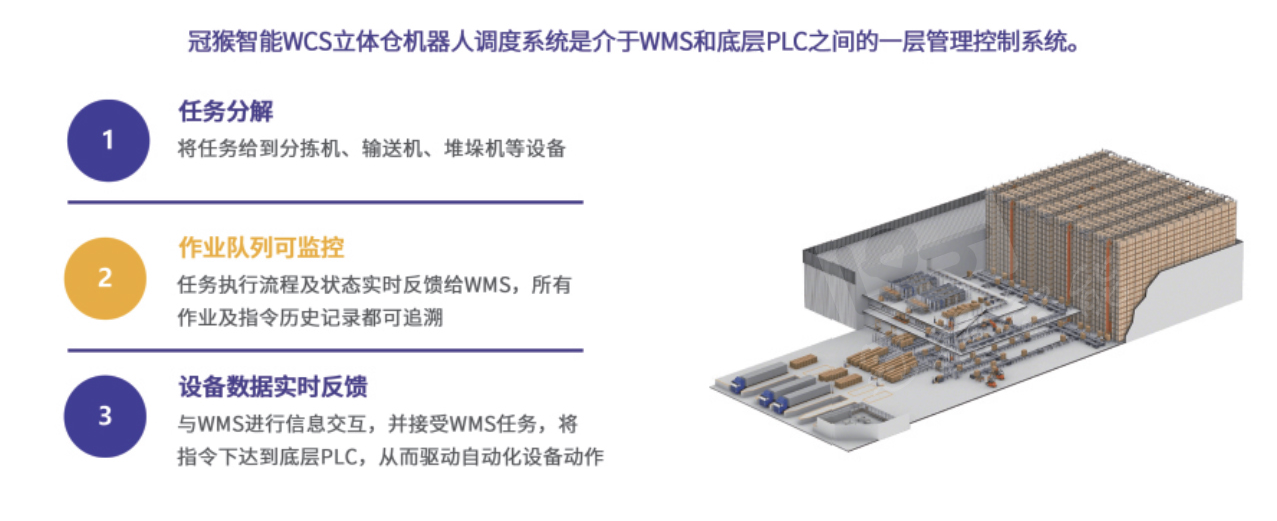

The types of warehouses that have been implemented include: raw material warehouse, semi-finished product warehouse, finished product warehouse, cold storage, and edge warehouse; The equipment that has been connected includes dozens of automation devices such as stacker cranes, four item vehicles, AGV carts, material box vehicles, conveyor lines, and robotic arms. It is a part of the logistics management system that manages and tracks orders placed by customers, dynamically monitors the progress and completion of orders, improves operational efficiency in the logistics process, saves operating time and costs, and enhances the market competitiveness of logistics enterprises..

Flexibly integrate with existing WMS/ERP/MES systems to reduce renovation costs.

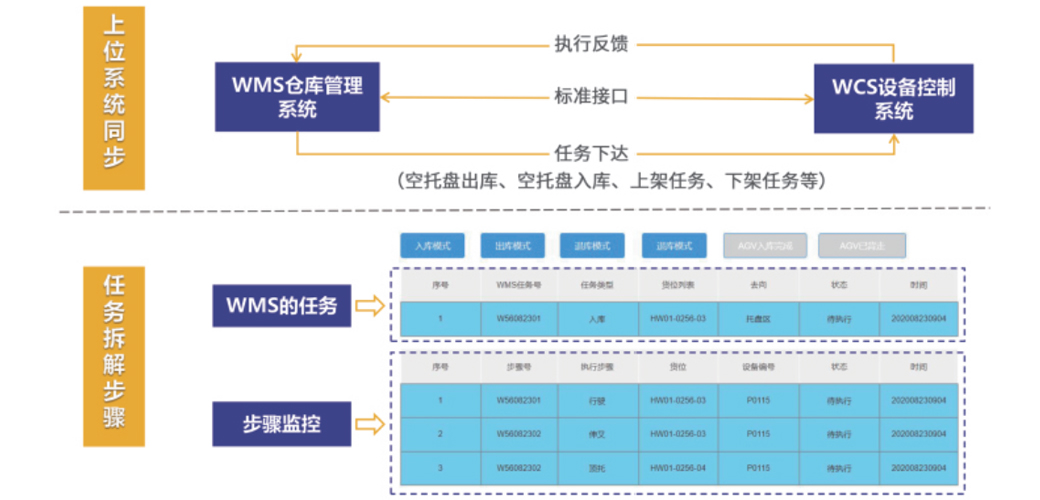

AI driven algorithms with operations research as the core; Develop real-time solutions that are task driven, optimize time and efficiency.

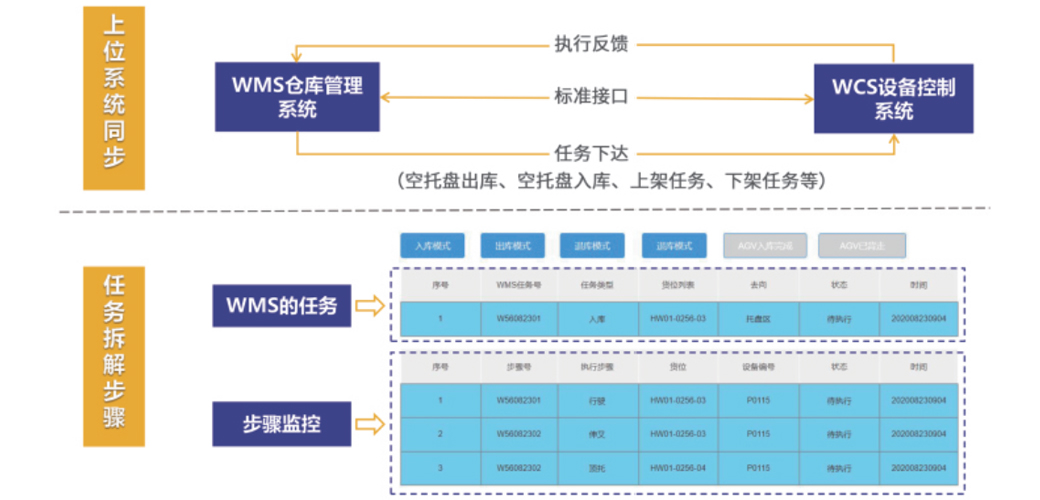

Starting from order lifecycle management, covering on-site operational processes; Dynamically match order demand with inventory status.

Flexible configuration of the operation of different devices; Integrate alarm signals from multiple devices and globally manage the health status of devices in the warehouse.

Support complex order warehouse operation processes and efficiency optimization; Support tasks such as shelving and returning in multiple storage locations.

An efficient visualization process configuration engine empowers customers with the ability to independently optimize business processes.

The types of warehouses that have been implemented include: raw material warehouse, semi-finished product warehouse, finished product warehouse, cold storage, and edge warehouse; The equipment that has been connected includes dozens of automation devices such as stacker cranes, four item vehicles, AGV carts, material box vehicles, conveyor lines, and robotic arms.