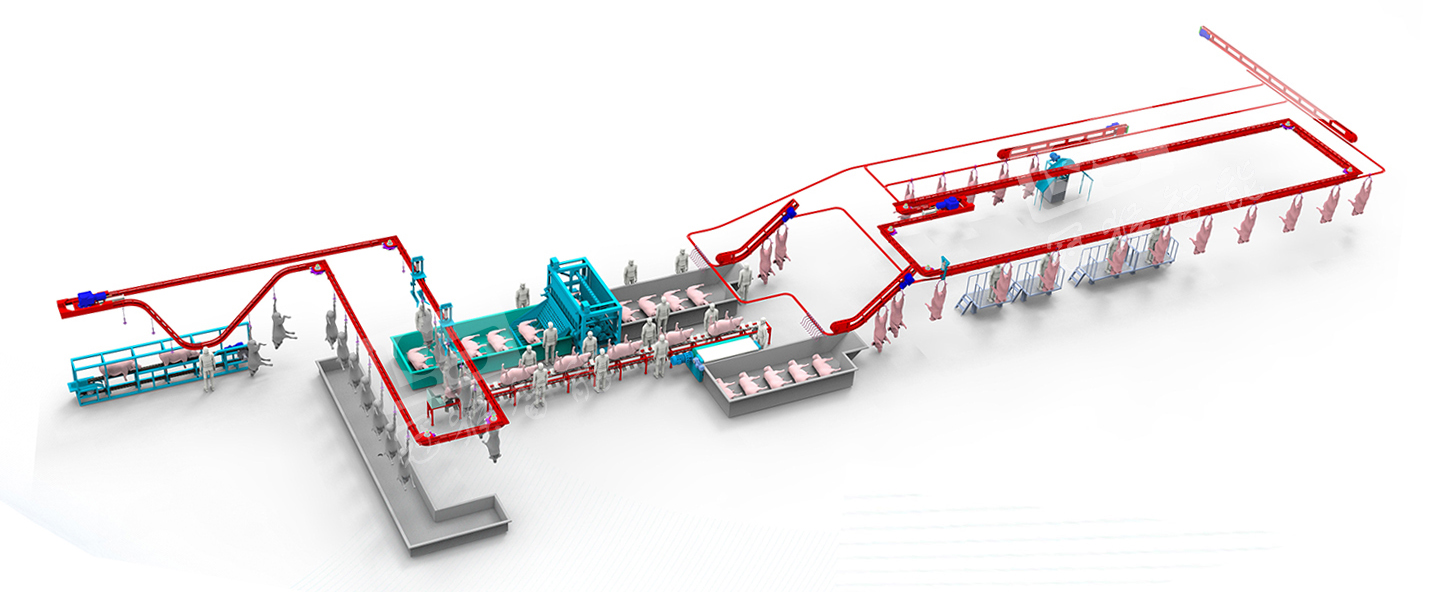

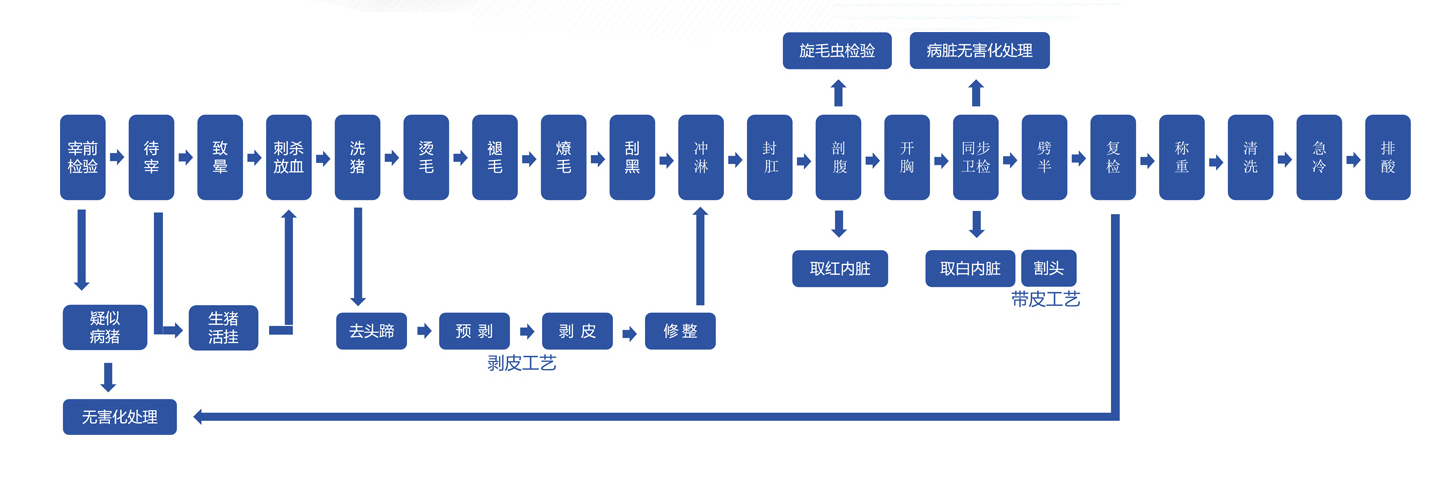

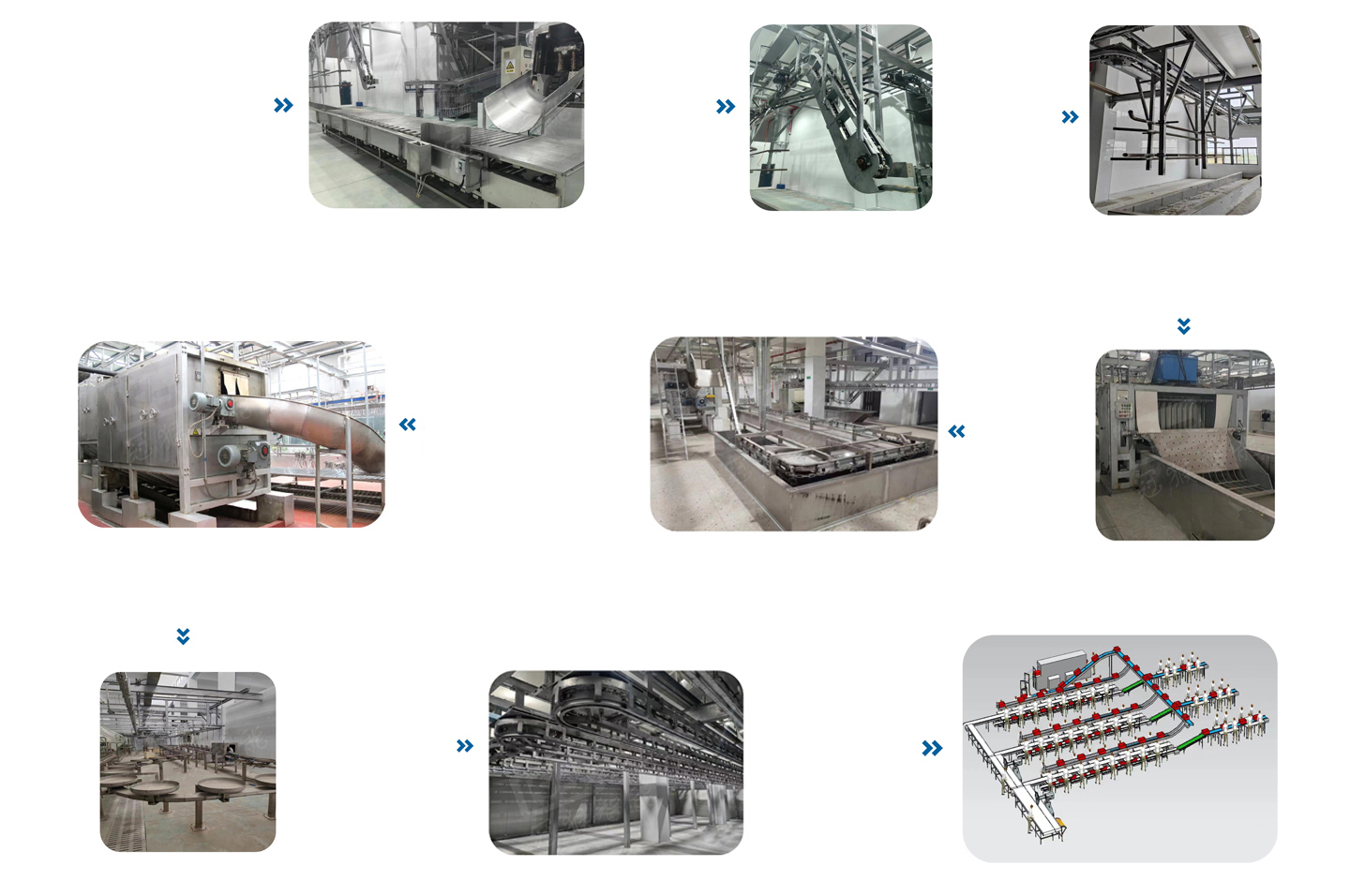

Electric stunning (horizontal bleeding)

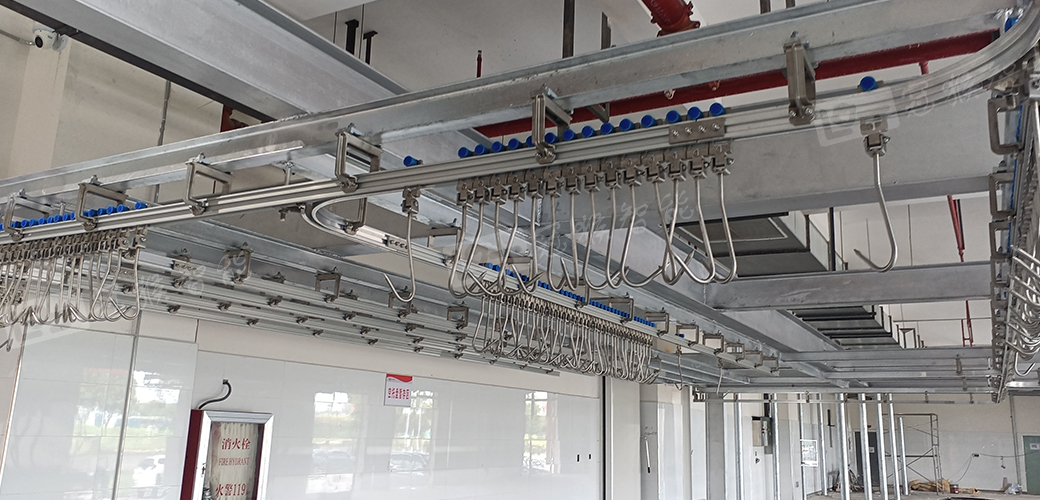

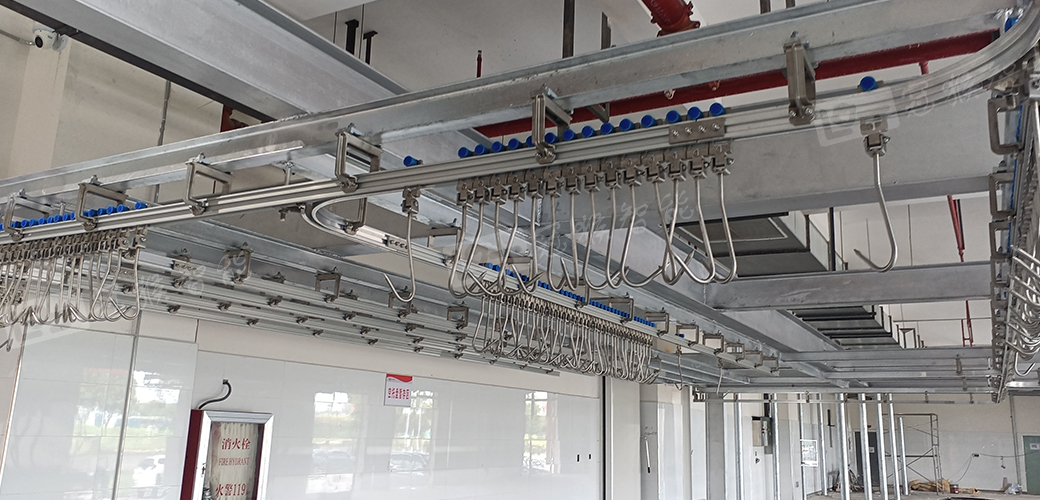

Trimming hoisting

Hanging bleeding

Traditional scalding, hair removal, and cleaing

Canal stvle scalding tunnel

Spiral dehairing, pig hair conveyin! and pig hair air blowing

Quarantine and transportatio of red and white viscera

Rapid cooling and conveying

Carcass segmentation

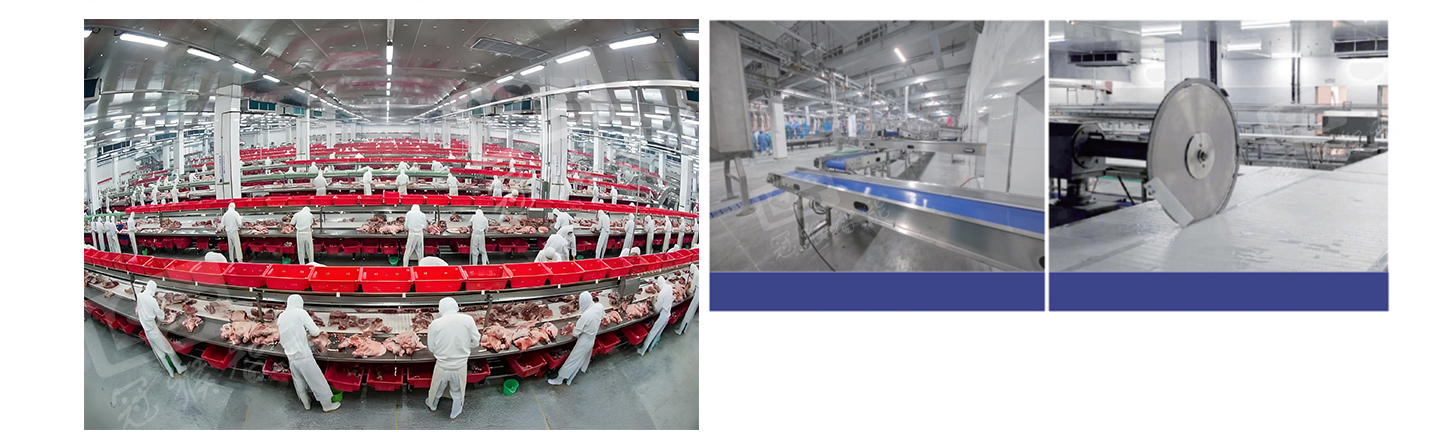

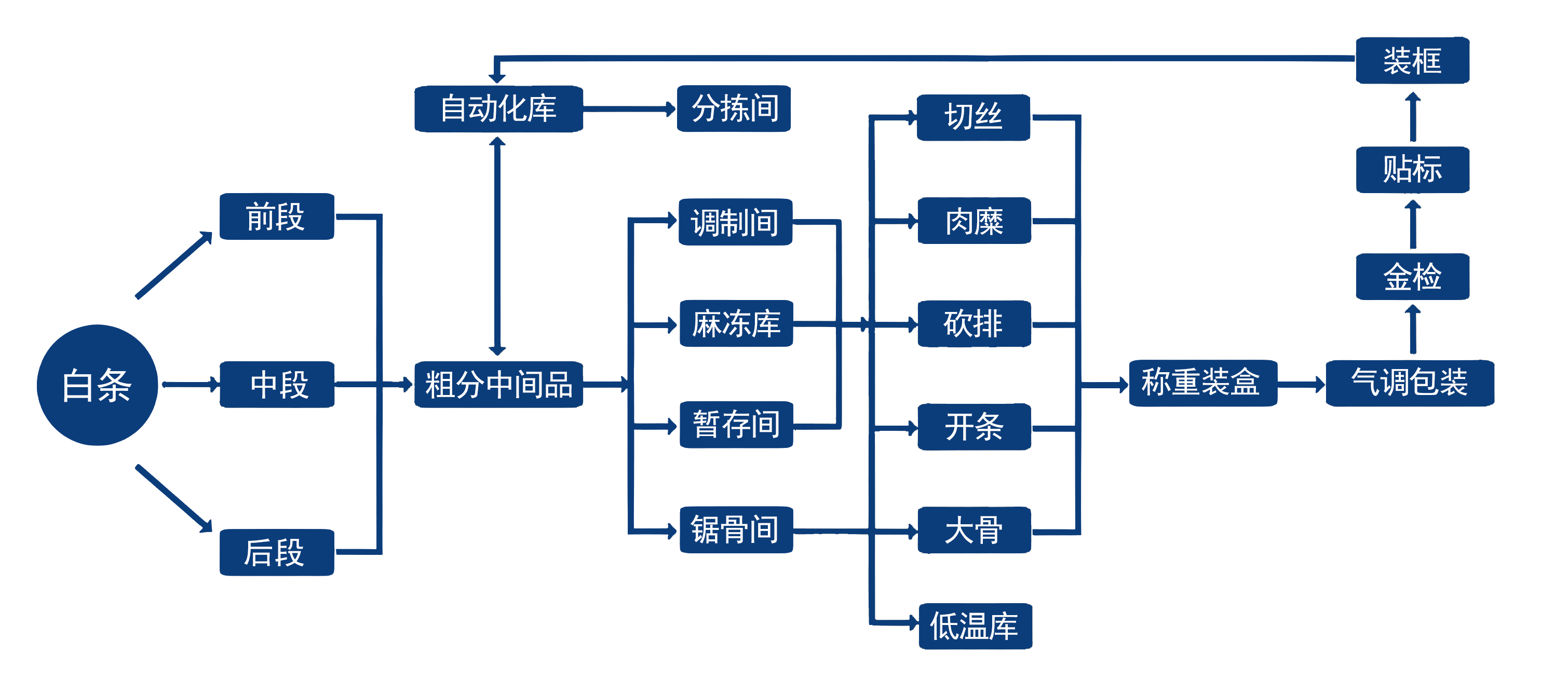

The Meat Cutting and Deboning Line is a key piece of equipment in the meat processing industry, which achieves efficient and precise meat cutting and deboning through automated technology and mechanical devices. This production line integrates advanced sensors, imaging technology, and intelligent control systems to ensure the accuracy of cutting and the thoroughness of deboning, significantly improving production efficiency and product quality. At the same time, it reduces the physical labor intensity and minimizes the impact of human factors on product quality. With the continuous advancement of technology, the Meat Cutting and Deboning Line is developing towards a more intelligent, energy-saving, and environmentally friendly direction to meet the growing demand for meat processing and the market's pursuit of high-quality products. The application of this equipment not only enhances the competitiveness of meat processing enterprises but also promotes the sustainable development of the entire industry.

Working in conjunction with manual labor, it processes various parts of pork, chicken, beef, mutton, and other meats, achieving automated operations such as deboning, cutting, and conveying in a streamlined production process.