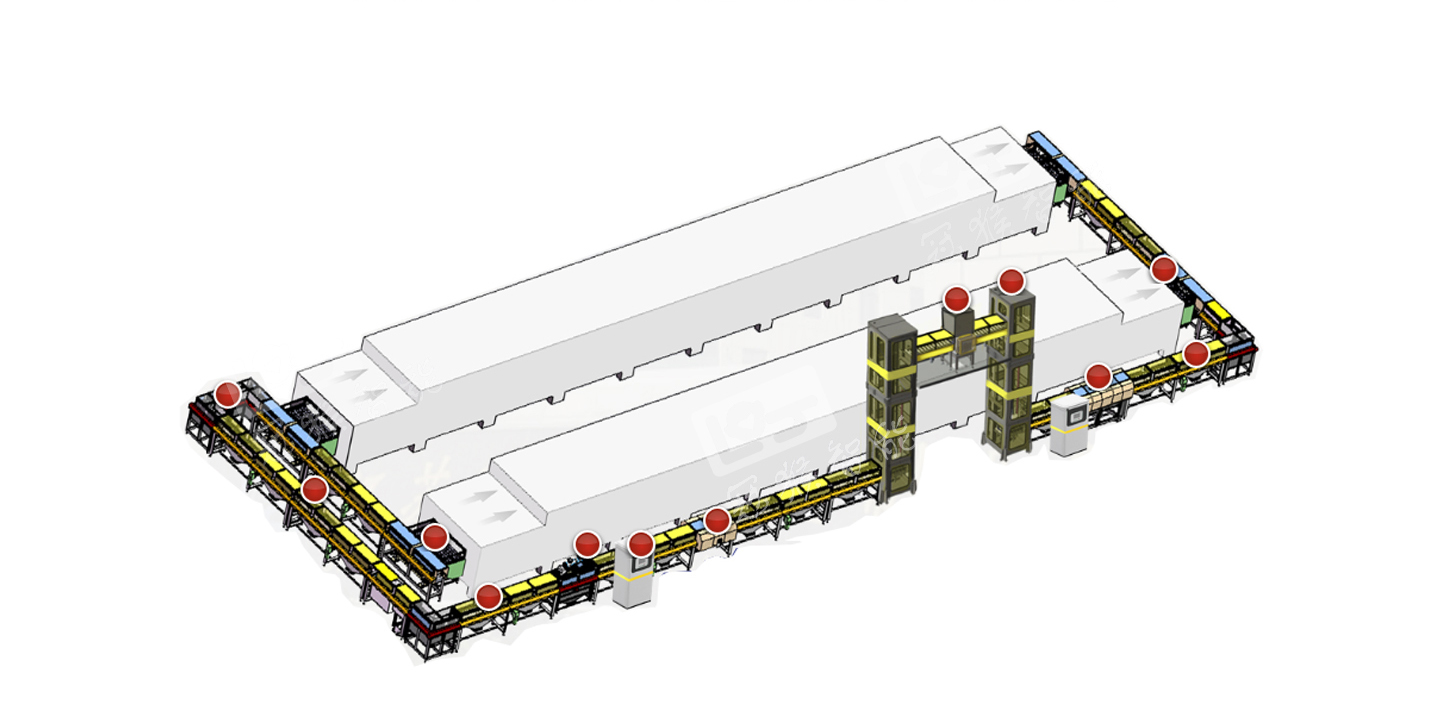

Lithium battery kiln external track automatic circulation line

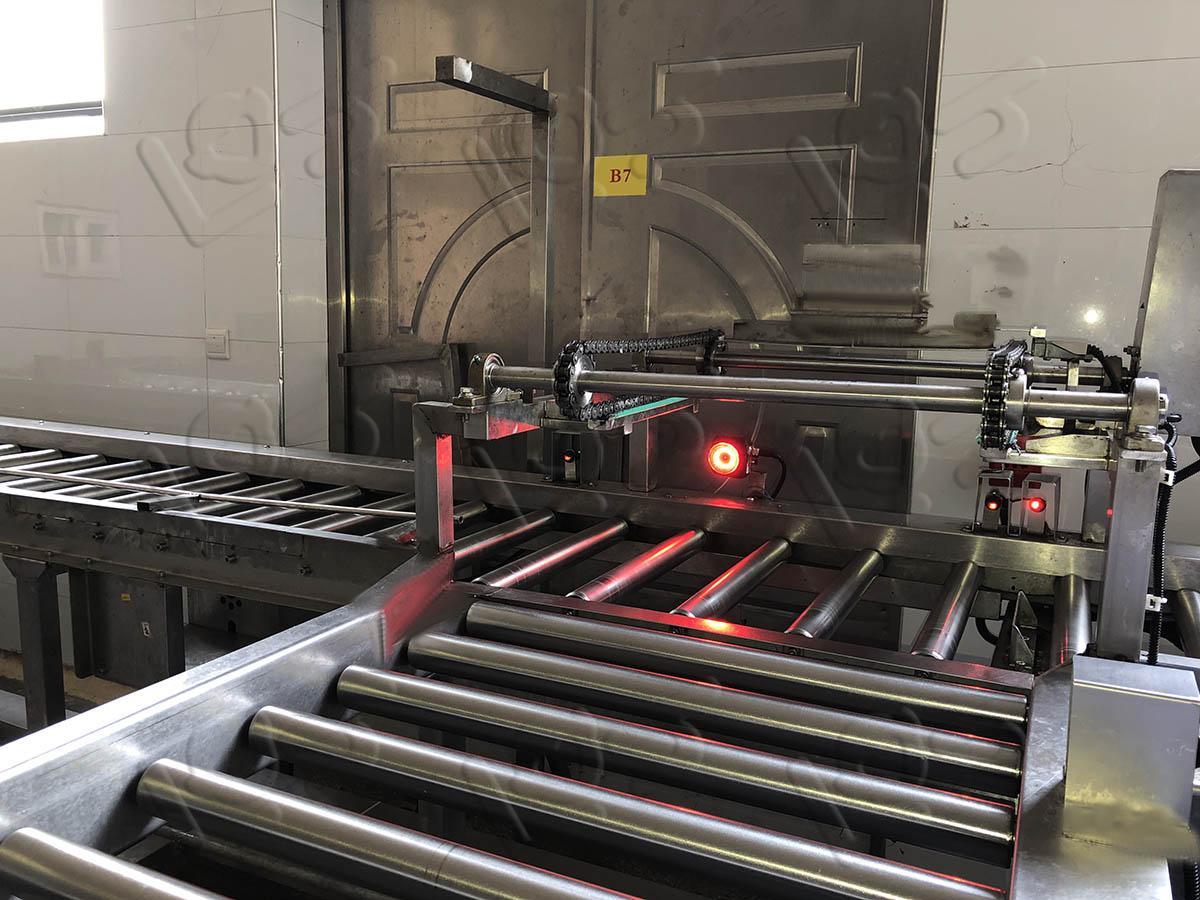

The Crown Monkey Intelligent Lithium Battery Kiln External Rail Automatic Circulation Line is used to achieve the pre process of quantitative filling, leveling, and cutting of powder raw materials before kiln sintering, while completing the post process of lifting, pouring, and cleaning after kiln sintering. The main equipment and material contact parts involved are made of non-metallic materials, and all equipment is mainly developed and designed for battery materials, suitable for lithium cobalt oxide, lithium phosphate, ternary materials, etc.