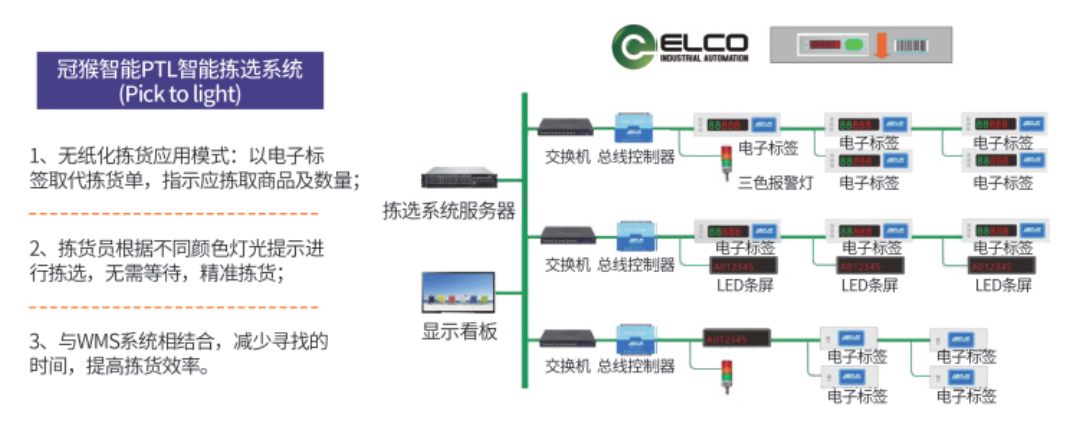

It is a paperless electronic information picking system, where picking personnel display quantities on electronic tags and complete picking tasks in a timely and accurate manner; With the help of a light picking system, sorting work is divided into three steps: "looking at the light", "picking", and "pressing", which improves picking efficiency and reduces error rates. It is a part of the logistics management system that manages and tracks orders placed by customers, dynamically monitors the progress and completion of orders, improves operational efficiency in the logistics process, saves operating time and costs, and enhances the market competitiveness of logistics enterprises..

The homework personnel quickly pick according to the electronic tag lighting prompt, replacing the time waste caused by manually searching for storage locations with paper documents.

There is a computer backend program that replaces manual comparison of paper documents, reducing dependence on people and avoiding human error in material retrieval, greatly safeguarding flexible production.

By displaying clear and concise instructions through electronic tags, material preparation can be shortened from one day to two hours, reducing inventory levels, saving warehouse space, and lowering inventory management costs.

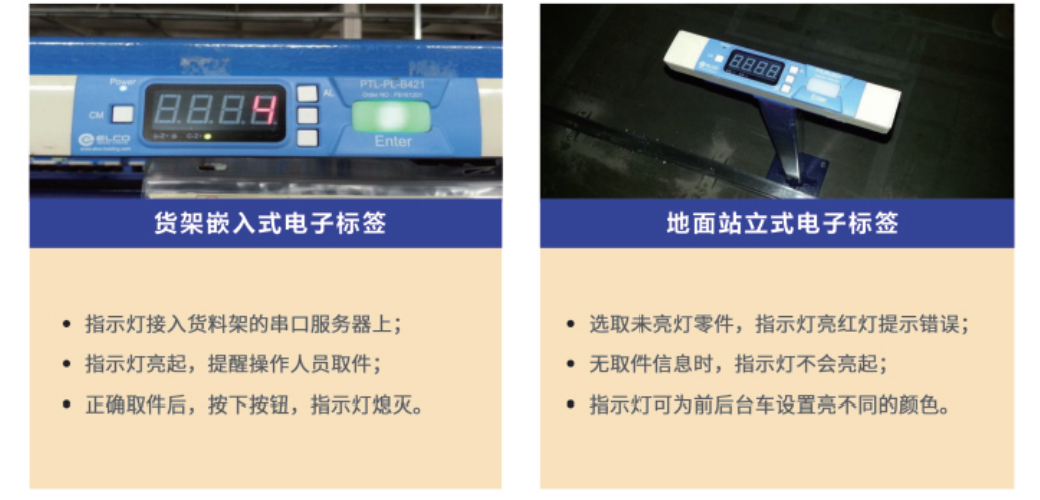

G3- Material corresponds to electronic tags, and the backend system lights up the electronic tags according to the task. Instruct the operators to quickly pick and reduce inventory throughout the entire process.

Paperless homework eliminates multiple manual operations such as printing/writing/checking paper materials and picking lists.

Integrated with WMS, no need for docking, can achieve instant broadcast and use.

Operators do not need training, scan the code to light up and locate, and quickly load and unload goods.

System big data calculation, location lighting and positioning, more accurate operation.

When the confirm button is pressed, it communicates with the software and the inventory data automatically increases or decreases.

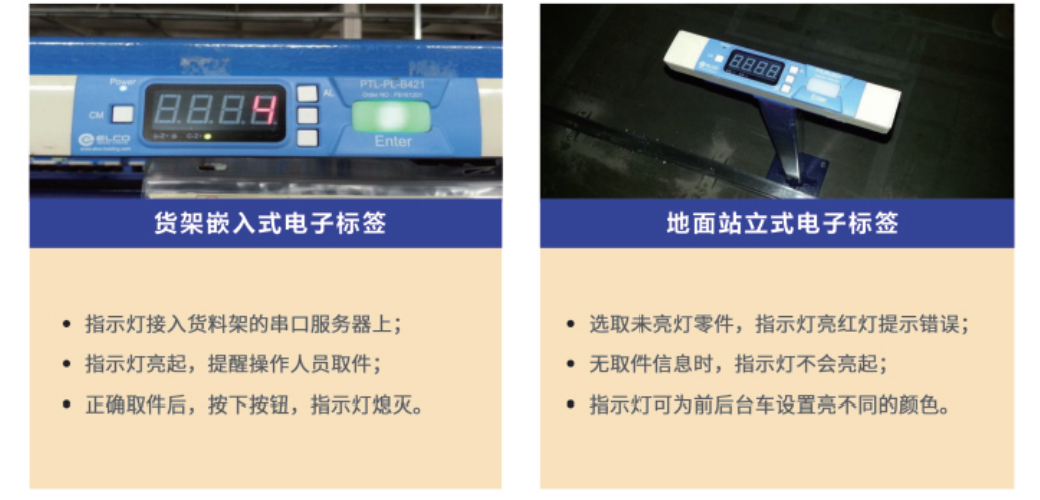

Different light colors and flashes can be flexibly combined for various business scenarios.

The electronic tag equipment developed by our company is flexible in application and has strong scalability. It is suitable for warehousing operations such as shelving, warehousing, picking, sorting, piece counting, and returns, making it easy for performance evaluation; By binding job numbers, personnel performance can be linked/ Different types of equipment such as dual depth, single station/multi station, straight track/transition, etc.