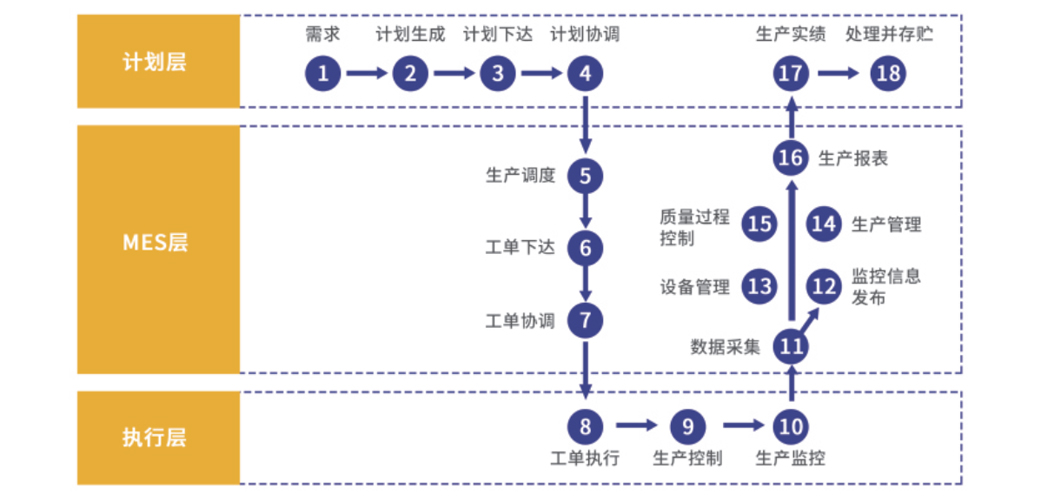

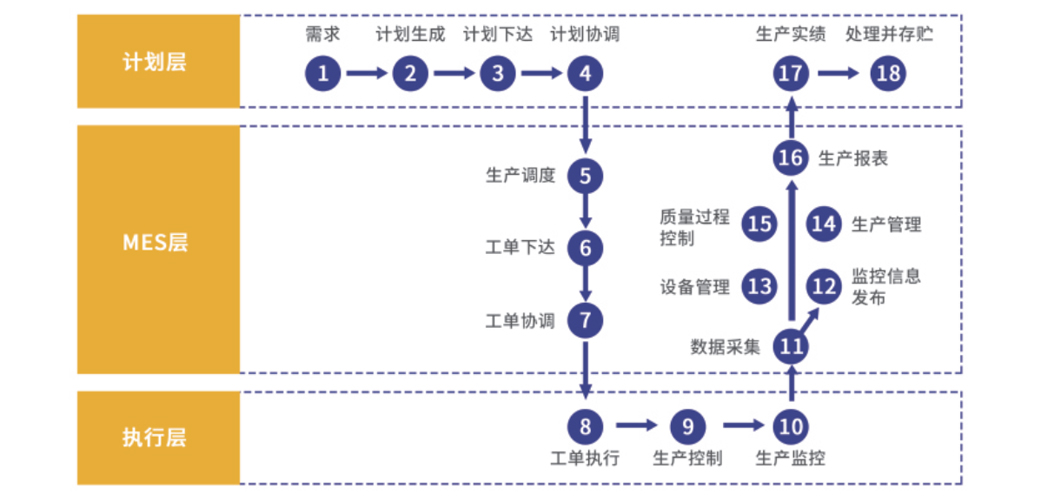

Embedding the lean management philosophy of the enterprise into it, it can be implemented from top to bottom, effectively ensuring the stable and orderly production of products.

Planning and Scheduling: Importing Workshop Operation Plans and APS Scheduling

Process connection: Design process data connection for on-site operation guidance

Logistics distribution: intelligent logistics distribution based on barcode RFID

On site execution: paperless on-site operation management

Quality Inspection: Digital Quality Inspection and SPC Control

Equipment monitoring: equipment status monitoring and data collection

Traceability analysis: full process quality traceability and statistical analysis

Kanban Report: Digital Kanban and Comprehensive Statistical Analysis

Building a manufacturing hub, improving business models, and achieving flexible collaboration and intelligent interoperability; So as to help enterprises achieve "quality improvement, cost reduction, and efficiency enhancement" and improve their market competitiveness.