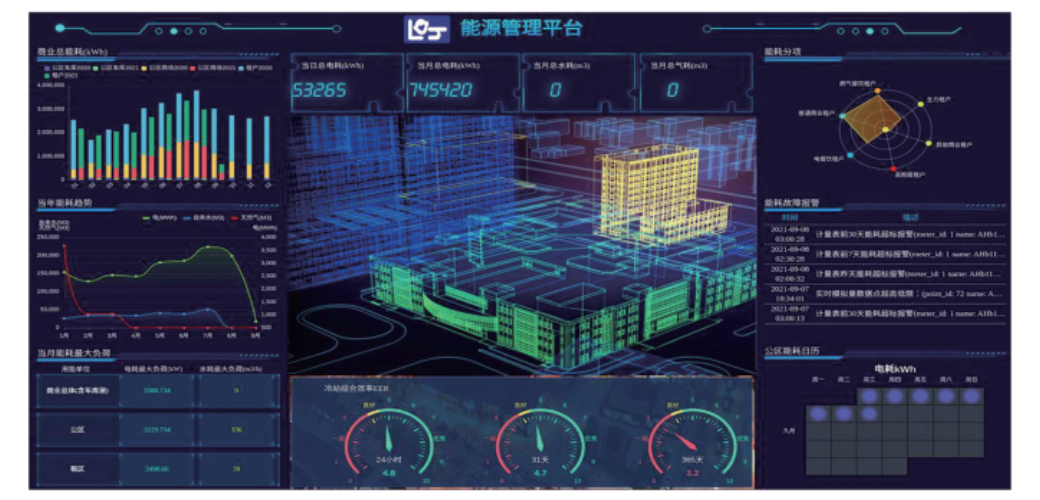

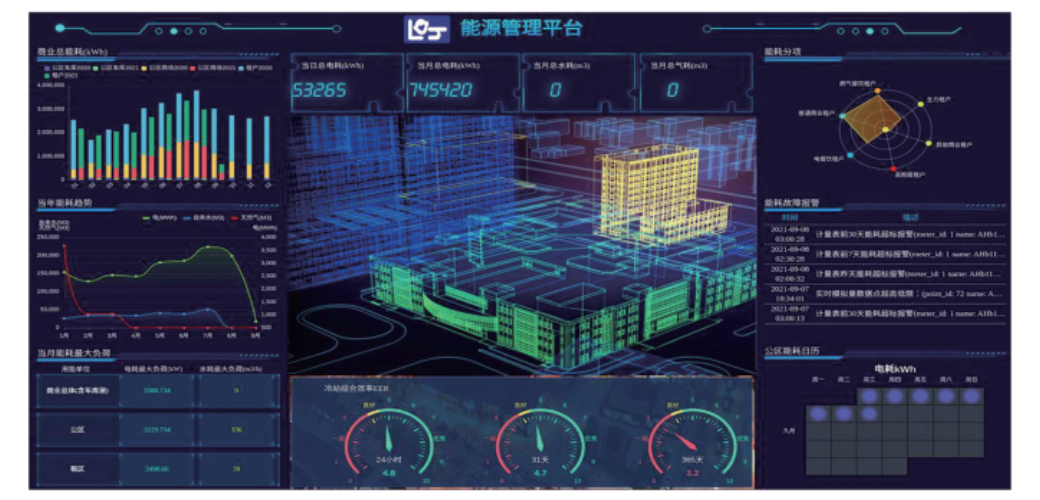

The Crown Monkey Intelligent EMS Energy Management System is customized and developed based on the energy consumption technology requirements of large public buildings and industrial enterprises, fully meeting the energy-saving renovation standards, green building evaluation standards, building intelligence acceptance standards, and building electrical energy-saving acceptance requirements of various new and existing buildings. The system supports real-time monitoring and statistical analysis of various energy forms including electricity, water, gas, oil, coal, etc., 24/7. The platform integrates advanced computer technologies such as the Internet of Things, big data, and 5G, providing comprehensive energy management for industrial enterprises and large public buildings through monitoring, diagnosis, analysis, energy-saving evaluation, and energy-saving improvement.

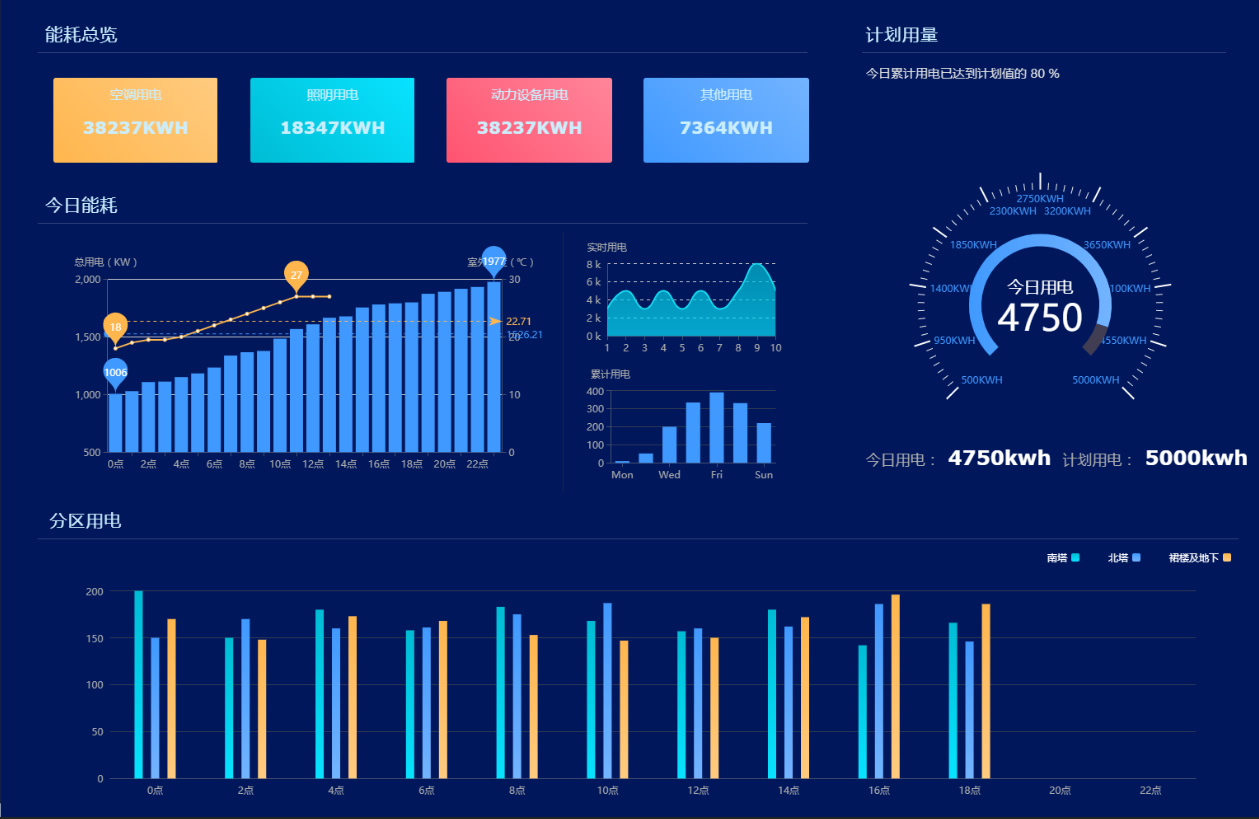

Display factory energy consumption performance in multiple levels, dimensions, and ways.

Identify the gap in energy efficiency levels through vertical benchmarking (comparison of historical best levels) and horizontal benchmarking (comparison of similar advanced enterprises).

Using the e-p analysis method, accurately analyze the impact of changes in logistics and energy flow per share on energy efficiency indicators, and identify energy-saving bottlenecks.

Automatically generate relevant charts and reports; Configurable data analysis capabilities.

Propose targeted and actionable phased energy-saving measures, technological energy-saving transformation, and process energy-saving transformation.

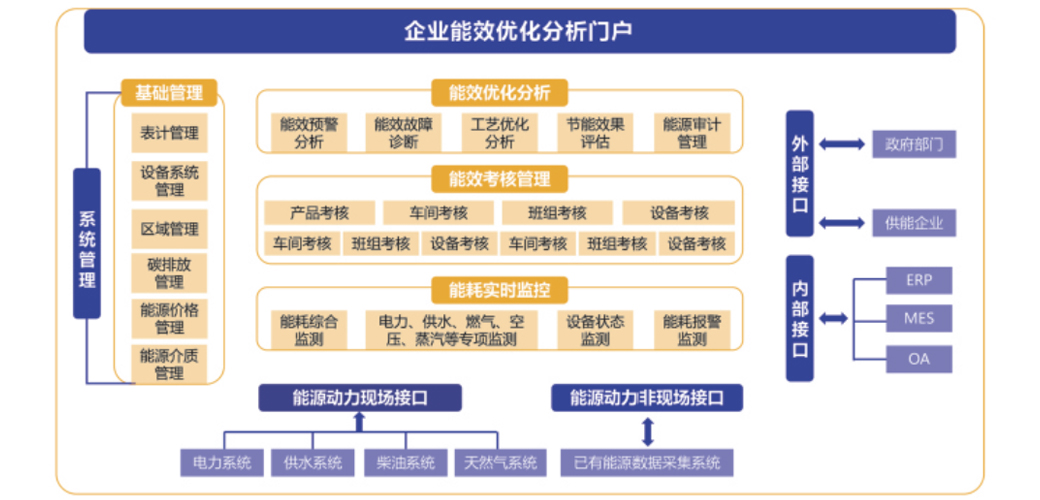

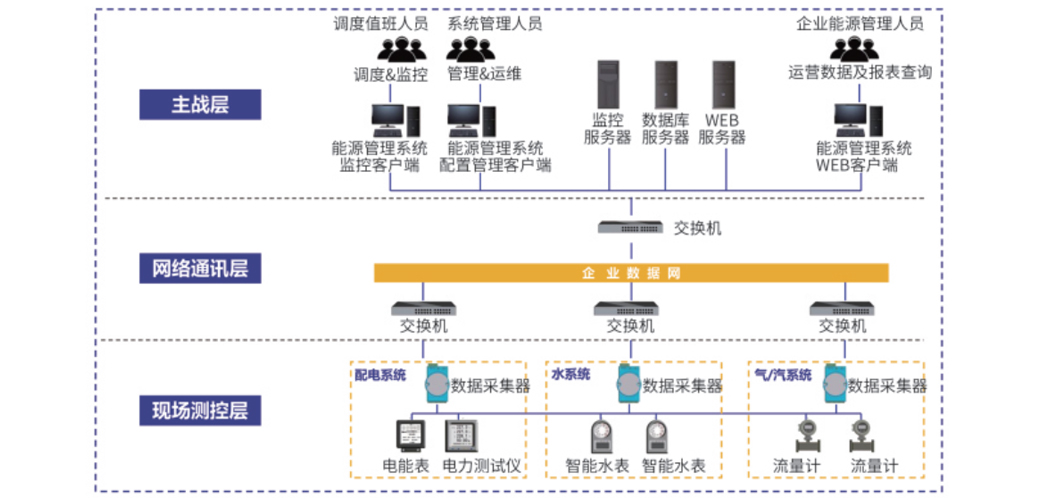

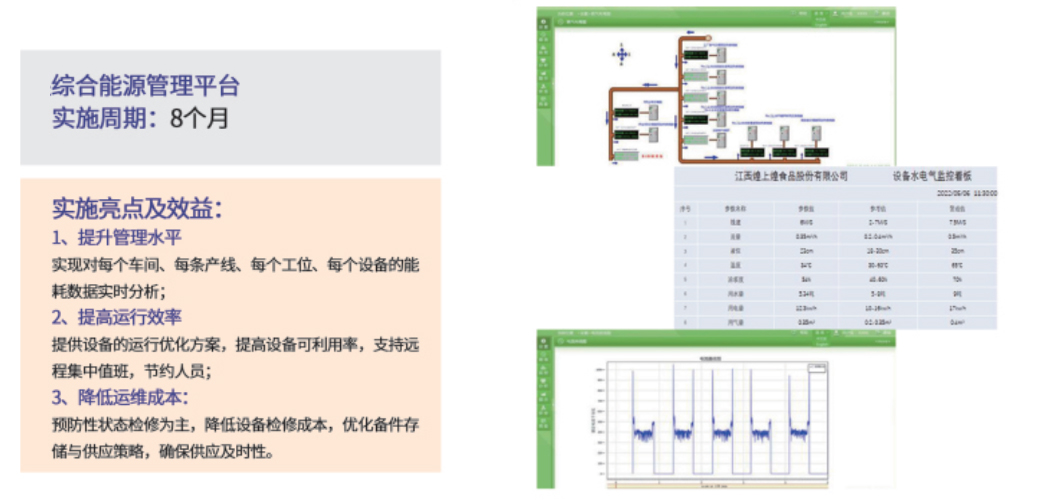

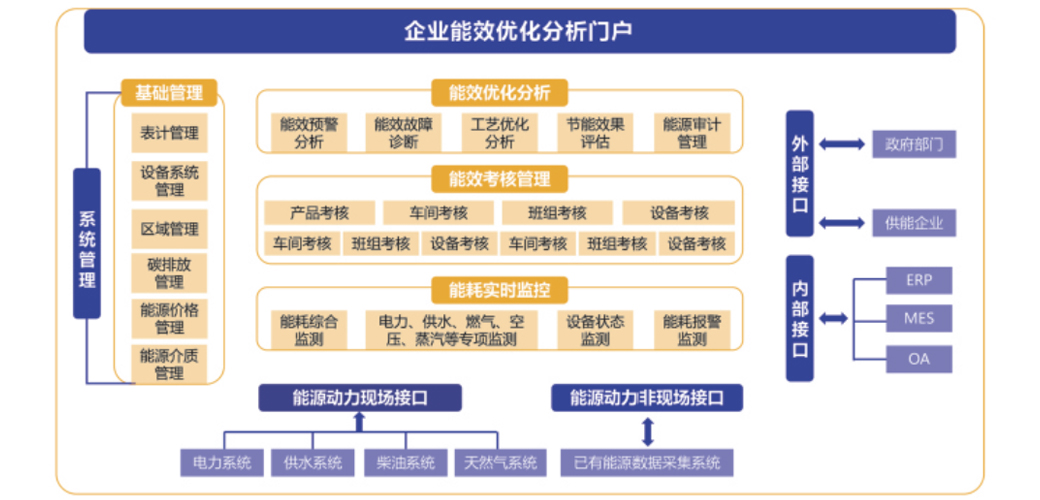

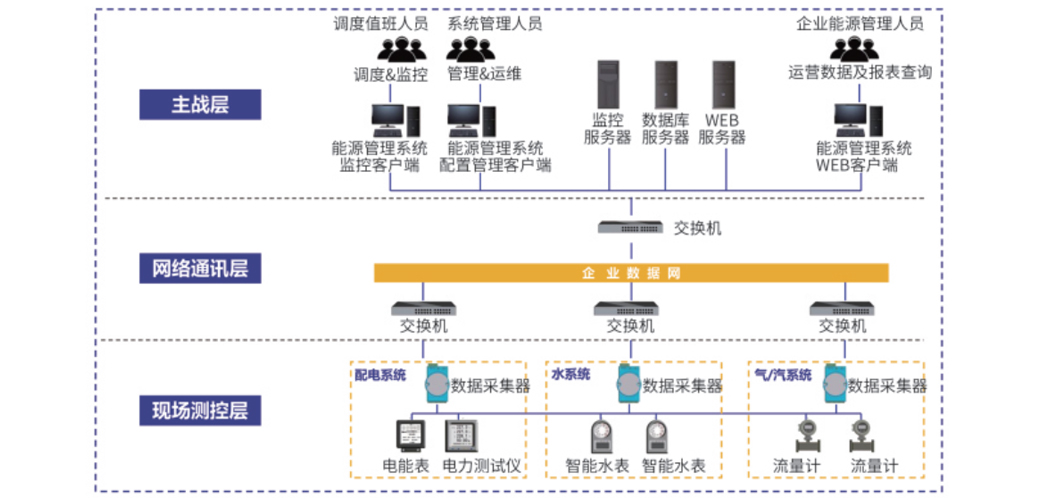

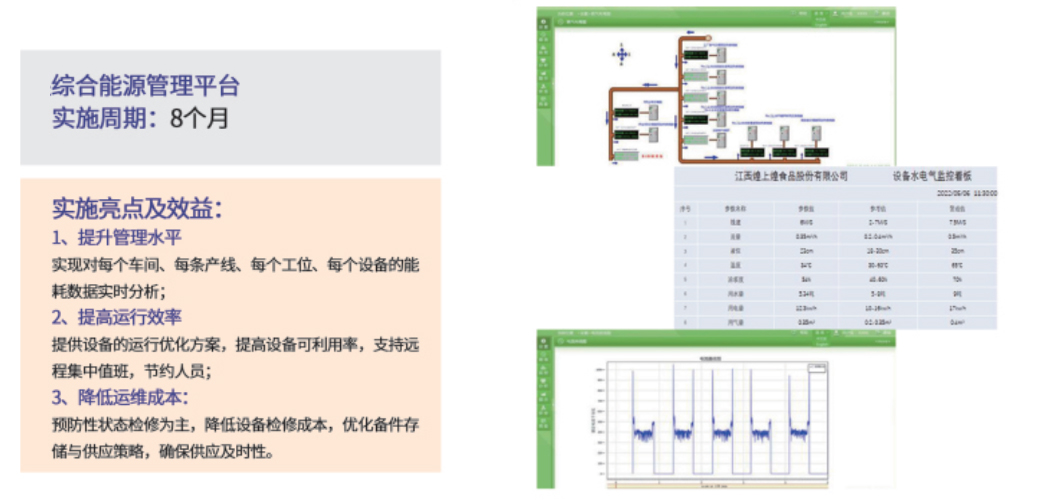

The energy efficiency management system refines equipment to the equipment level or production line level through the implementation of energy metering transformation. By using signal acquisition, communication, protocol conversion and other technical means, the collection of energy medium parameters is isolated from the production control system, providing continuous, authentic and reliable data basis. Using industrial grade Ethernet switches, establish a real-time data server to achieve online energy data collection, automatic statistics, and storage at the minute and second level. Establish a data channel with the production system to lay the foundation for assessment and analysis. Organic integration with ERP, MES, OA, etc. lays the foundation for integrated management and control.

The energy efficiency management system can demonstrate the relationship between energy input, conversion, and usage. Clearly display which energy sources the enterprise purchases, what conversions are made, what energy sources are used in each workshop, and how much is used. Real time monitoring of energy consumption, real-time flow, and quality parameters of key process links. Real time monitoring of production parameters can accurately calculate the energy consumption per unit of each product series, providing a basis for accurate cost assessment of product series and a foundation for scientific energy cost allocation.

The energy efficiency management system can monitor the real-time operation status of energy transmission pipelines and equipment, and can use parameters such as current, power, instantaneous flow rate of energy consuming media, pressure, temperature, etc. as the basis for equipment diagnosis and operational efficiency analysis. Monitoring key equipment can determine the operating status, such as shutdown, standby, normal operation, overload, etc. Different colors of parameters indicate the operating status of different equipment, timely detect leakage and leakage phenomena, discover energy-saving space, and realize the possibility of energy conservation from the perspective of management.

The energy efficiency management system can combine energy consumption and output data to determine the target energy consumption per unit of each process product, optimize production scheduling based on peak, valley, and average electricity prices, and assess and manage the implementation of off peak electricity consumption targets for workshops, production lines, and equipment. Energy consumption data can be collected at the minute level, accurately attributed to the team, and then the total energy consumption and per unit energy consumption of each team can be calculated based on the team's output. Attributing energy consumption to workshops, production lines, and equipment, identifying energy efficiency differences between production units, and providing reference for prioritizing the renovation of inefficient equipment, purchasing efficient equipment, and scheduling efficient equipment.

The energy efficiency management system can perform statistical analysis on energy consumption, and collect energy consumption data according to different time periods, regions, energy categories, or types of energy consuming equipment. After analyzing the total energy consumption, unit area energy consumption, per capita energy consumption, standard coal conversion, and historical trends, as well as comparing energy data during the same period, real-time curves, historical curves, predictive curves, real-time reports, historical reports, daily/monthly reports and other data are automatically generated to provide a basis for energy-saving management, data analysis for technical energy conservation, and predict energy consumption trends.

The energy efficiency management system identifies energy-saving directions and explores skill space through energy balance analysis. Analyze based on process parameters, provide data analysis tools, and discover optimized combinations of process parameters. Establish an energy-saving optimization scheduling plan through energy efficiency assessment and predictive analysis. Optimize production process parameters through energy efficiency factor correlation analysis. Establish an energy efficiency warning model, mine historical data, identify energy consumption operating patterns, and promptly remind maintenance of equipment when energy efficiency decreases.

The energy efficiency management system can monitor the operating status of environmental protection equipment, and monitor, analyze, and manage emissions such as water and smoke. Online regulation of various energy media, fully utilizing secondary energy, ensuring the rational operation of production economy, and achieving energy-saving and environmental benefits. In the event of energy system abnormalities and accidents, timely, rapid, and accurate disposal can be carried out to minimize the impact of energy system failures and ensure the safe operation and stable energy supply of energy equipment.

Realize the openness and transparency of energy consumption data, implement energy quota management and low-cost energy-saving management, and establish a scientific energy-saving management system.